What is the electrical connector?

What is the electrical connector?

Nov 23,2023

An electrical connector is a device designed to connect circuits or components, allowing for the transmission of electrical signals, power, or data between them. These connectors come in various shapes, sizes, and designs to facilitate the connection and disconnection of wires or cables in various electronic and electrical systems. They play an important role in establishing reliable and safe electrical contacts, ensuring the effective operation of equipment and systems from consumer electronics to industrial machinery. The characteristic of electrical connectors is their specific characteristics, such as conductor material, insulation type, and locking mechanism, which can meet the different requirements of different applications.

What is the rated voltage of the electrical connector?

The rated voltage of an electrical connector refers to the maximum voltage designed for safe operation without the risk of electrical breakdown or failure.

The specific rated voltage of electrical connectors can vary greatly depending on their intended application and design. Connectors used in low-voltage applications, such as those in consumer electronics, may have a lower rated voltage, typically in the range of a few volts to a few hundred volts.

In contrast, connectors designed for high-voltage applications, such as industrial machinery or distribution systems, can have higher rated voltages, reaching several thousand volts or even higher.

It is crucial to choose connectors with appropriate rated voltage to ensure the safe and reliable operation of the electrical system while avoiding potential electrical hazards.

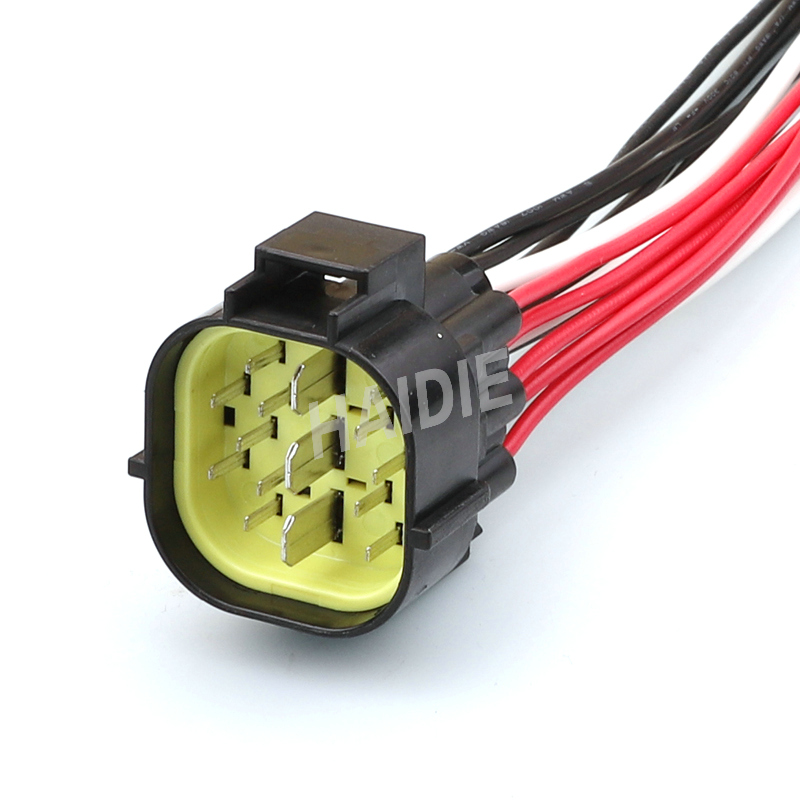

How many pins does the electrical connector have?

The number of pins varies for different types of electrical connectors. Connectors can have multiple pin configurations, some with only a single pin for basic connections, while others can have multiple pins arranged in specific patterns or rows.

The number of pins in an electrical connector is determined by the requirements of the electrical system it serves. For example, connectors in complex electronic devices can have many pins to adapt to various signal, power, or data transmission needs. When selecting connectors, it is necessary to consider the number of pins to ensure compatibility with the specific wiring and connection requirements of the application.

What kind of material is the electrical connector made of?

Common materials for electrical connectors include:

Metal Alloys: Many connectors use metal alloys such as brass, copper, or aluminum for their conductive properties.

Insulating Materials: The body of the connector is often made from insulating materials to prevent electrical contact between pins or terminals. Common insulating materials include plastics (such as PVC, polyethylene, or polycarbonate) and thermosetting materials (like phenolic or epoxy).

Coatings: Connectors may have coatings or platings to enhance their durability, conductivity, and resistance to corrosion. Common coatings include gold, silver, nickel, or tin.

Sealing Materials: In connectors designed for outdoor or harsh environments, sealing materials like rubber or silicone may be used to protect against moisture and contaminants.

Can the electrical connector be customized to meet special requirements?

Yes, electrical connectors of YUEQING HAIDIE are often designed with customization in mind, allowing them to be tailored to meet special requirements.

Customization options may include variations in the number and arrangement of pins, specific materials to suit environmental conditions, unique form factors, or specialized coatings for enhanced performance.

YUEQING HAIDIE ELECTRIC CO.,LTD offer customization services to meet the diverse needs of various industries and applications. This flexibility ensures that electrical connectors can be adapted to specific technical, mechanical, or environmental specifications, providing a solution that aligns precisely with the requirements of a particular application or system.

Is the electrical connector waterproof and flame retardant?

The waterproof and flame retardant properties of an electrical connector depend on its design, construction, and the materials used. Some electrical connectors are specifically engineered to be waterproof, incorporating seals, gaskets, or special coatings to protect against moisture and environmental elements. These connectors are commonly used in outdoor or marine applications.

Similarly, flame retardant connectors are designed to minimize the risk of fire by using materials that resist combustion or delay the spread of flames. Flame retardant connectors are often required in applications where fire safety is a critical consideration, such as in industrial settings or electronic devices.

YUEQING HAIDIE ELECTRIC provides product specifications to determine whether a specific electrical connector is waterproof, flame retardant, or has any other required characteristics.